Standard Barrel Pumps

Meter/Pump From 55 Gallon Drums with the Iris IBMP

IRIS IBMP: A Submersible, Precision Metering Pump

The In-Barrel Metering Pump (IBMP) from Iris Engineering is designed for precise metering of liquids and additives in a variety of applications where these fluids must be metered from barrels, drums or tanks to a process.

Combining Precision With Versatility

Compare these features with any conventional metering pump and you'll see why the IBMP is fast becoming the standard in precision metering:

- Accuracy to 0.25%

- Pressure to 650 psi

- Flows 10 to 3600 cc/min.

- Viscosities 1 to 25,000 cps

- Repeatable

- Virtually pulseless

- Various control options

The IBMP features a rotary, positive displacement sealless pump which provides a precise, pulseless flow which is easily controllable and repeatable regardless of discharge pressure. And, because the pump is fully submerged at the bottom of the barrel, it can never leak or lose its prime as it meters the liquid down to the last 1/8 of an inch.

Highest Performance at Low Cost

The IBMP is an economical complete system (control, motor and pump) which eliminates costly setups of holding tanks, transfer pumps, check valves, piping and metering pumps. And, because the IBMP is portable, it easily integrates directly into the process and is easy to set up and operate. Precise construction and only three moving parts ensure long life and low maintenance costs.

Typical Applications for the IBMP

- Urethane

- Adhesives

- Paint and Dies

- Finishes

- Lubricants

- Additives

- Water Treatment Chemicals for

pH adjustment, polymer addition

Want to specify or order a standard IBMP?

IBMP Applications

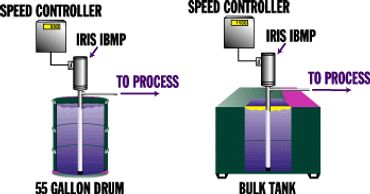

Precision Metering from Drums or Tanks

High Pressure Metering to Critical Process

Precision Metering from Drums or Tanks

The portable IBMP allows the fluid to be conveniently positioned near the process.

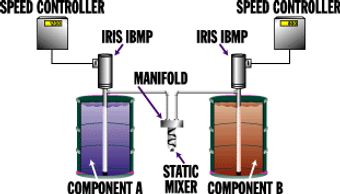

Two Component Ratio Mixing

High Pressure Metering to Critical Process

Precision Metering from Drums or Tanks

Closed-loop control of independent streams according to ratio set by process recipe.

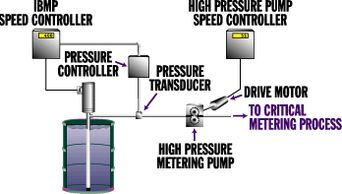

High Pressure Metering to Critical Process

High Pressure Metering to Critical Process

High Pressure Metering to Critical Process

IBMP provides a controlled pressure to the input of a high pressure metering pump for greater accuracy with pulseless flow (especially well suited for high pressure metering of low viscosity fluids)

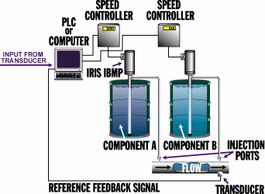

Integration Into Closed Loop Control System

Integration Into Closed Loop Control System

High Pressure Metering to Critical Process

PLC or computer acts both as process monitor and controller for the IBMP to maintain process parameters.

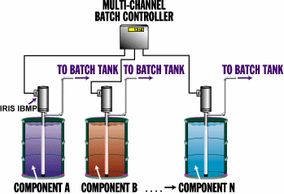

Multi-Component Batch Mixing

Integration Into Closed Loop Control System

Multi-Component Batch Mixing

Multi-channel controller functions as pre-set totalizer to meter any number of fluids for repeatable batch recipe.

Copyright © 2019-2024, Iris Engineering - All Rights Reserved.